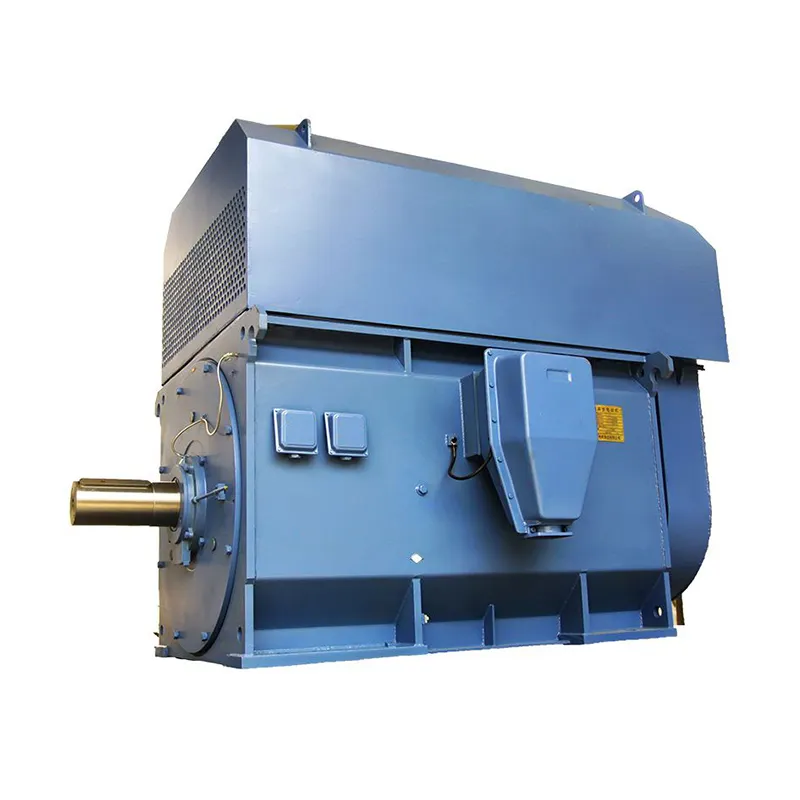

High voltage DC motors are emerging as valuable assets in power plants, supporting critical operations across diverse energy generation systems, including thermal, nuclear, and renewable facilities. Operating at voltages typically between 600V and 3kV, these motors offer unique advantages such as precise speed control, high starting torque, and efficient performance under varying load conditions, making them suitable for powering essential auxiliary equipment. In thermal power plants, high voltage DC motors drive boiler feed pumps, which supply water to high pressure boilers at consistent flow rates. Their ability to deliver high torque at low speeds ensures reliable operation even when pumps are handling high pressure water, often exceeding 100 bar. Additionally, they power induced draft and forced draft fans, where variable speed control—enabled by DC drives—optimizes air flow for combustion, enhancing fuel efficiency and reducing emissions. In nuclear power plants, where safety and reliability are paramount, these motors operate in demanding environments with radiation exposure, requiring specialized insulation and enclosure materials resistant to radiation induced degradation. They drive coolant pumps that circulate water through reactor cores, with redundant systems to ensure uninterrupted operation. High voltage DC motors also find applications in renewable energy plants, such as concentrated solar power (CSP) facilities, where they power heat transfer pumps and tracking systems for solar collectors, requiring precise speed adjustment to align with solar intensity. The robust design of these motors includes heavy duty bearings, efficient cooling systems (liquid cooled for high power applications), and reinforced windings to withstand continuous operation. DC drives integrated with these motors enable soft starting, reducing mechanical stress on connected equipment and minimizing inrush currents that could strain plant electrical systems. Furthermore, their efficient energy conversion helps reduce auxiliary power consumption, a significant factor in overall plant efficiency, as auxiliary systems can account for 5 10% of a power plant’s total energy output. Advanced monitoring systems, including sensors for temperature, vibration, and current, facilitate predictive maintenance, ensuring early detection of potential issues and minimizing unplanned downtime. By combining reliability, efficiency, and precise control, high voltage DC motors contribute to the stable and cost effective operation of power plants across various energy generation technologies.