In the world of heavy equipment, three-phase asynchronous motors are the workhorses that factories can’t afford to change. They’re known for getting more done with less energy, running longer without breaking, and fitting into almost any machine you can stake on a shop floor. Let’s break down where these motors are used, why businesses trust them, and the edge they have over other motors.

What They Are and How They Work

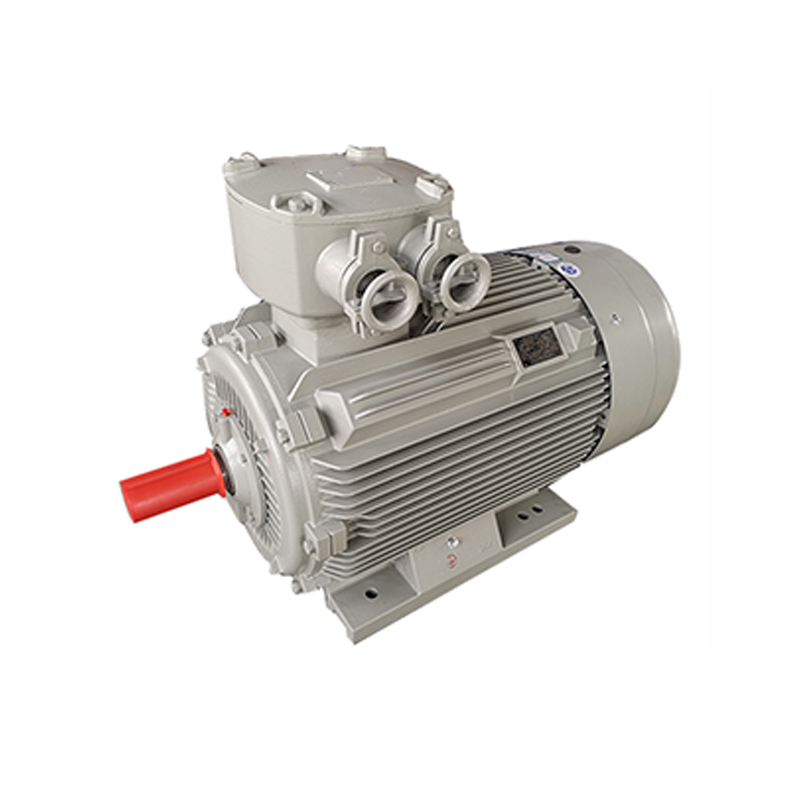

Three-phase asynchronous motors, a.k.a. induction motors, turn electricity into motion through electromagnetic wizardry. When you hook up three-phase AC to the machine, the coil in the stator creates a moving magnetic field. The rotor gets dragged along without ever touching it. Since there’s no commutator or brushes to wear out, the design is built for running 24/7 in the toughest conditions. When you think high duty, think induction.

Core Uses in Manufacturing

Manufacturers lean on three-phase asynchronous motors to power almost everything that keeps a production line moving. Think of the conveyors that shuttle parts, the pumps that keep fluids circulating, the compressors that provide pressurized air, and the lathes that shape metal. They do these chores while lugging heavy loads and shifting speed on-the-fly without breaking a sweat. Durability is baked in, so the motors keep churning through the years with so little maintenance that they silence production managers’ worries over downtime. For any plant where every second counts, these motors are a no-brainer.

Role in HVAC Systems

Three phase asynchronous motors are key players in heating, ventilation, and air conditioning (HVAC) systems. You’ll find them driving fans, blowers, and chillers, making sure air moves and temperatures stay in check. These motors offer variable-speed control, which means air can be directed exactly where it’s needed, saving energy and improving comfort in both homes and businesses. By fine-tuning airflow, they help keep indoor air fresh and reduce energy bills, showing why they’re essential in today’s energy-conscious buildings.

Contribution to Renewable Energy

With the global push for greener power, three-phase asynchronous motors are showing up more in wind and solar energy setups. In wind turbines, they can be converted into generators that turn spinning blades into usable electricity. Their sturdiness and low upkeep suit them perfectly for the remote hills and fields where wind farms are built. These turbines help reduce carbon footprints, and the motors’ efficient design supports the bigger picture of shared, sustainable energy.

Future Trends and Innovations

Looking ahead, the outlook for three-phase asynchronous motors is bright, driven by steady improvements in both technology and the materials used. Smart motors now come with built-in Internet of Things (IoT) sensors, enabling continuous, real-time tracking and predictive maintenance. This feature boosts energy efficiency, lowers operating expenses, and extends the replacement cycle. Coupled with cutting-edge control systems, these motors deliver powerful, adaptable performance for a range of uses, keeping them a leading choice in industrial settings.

In summary, three phase asynchronous motors power everything from factories to wind turbines. Their reliability, efficiency, and ease of integration make them a go to technology across sectors. As future innovations unfold, further upgrades are expected, cementing their role as the backbone of modern industry.