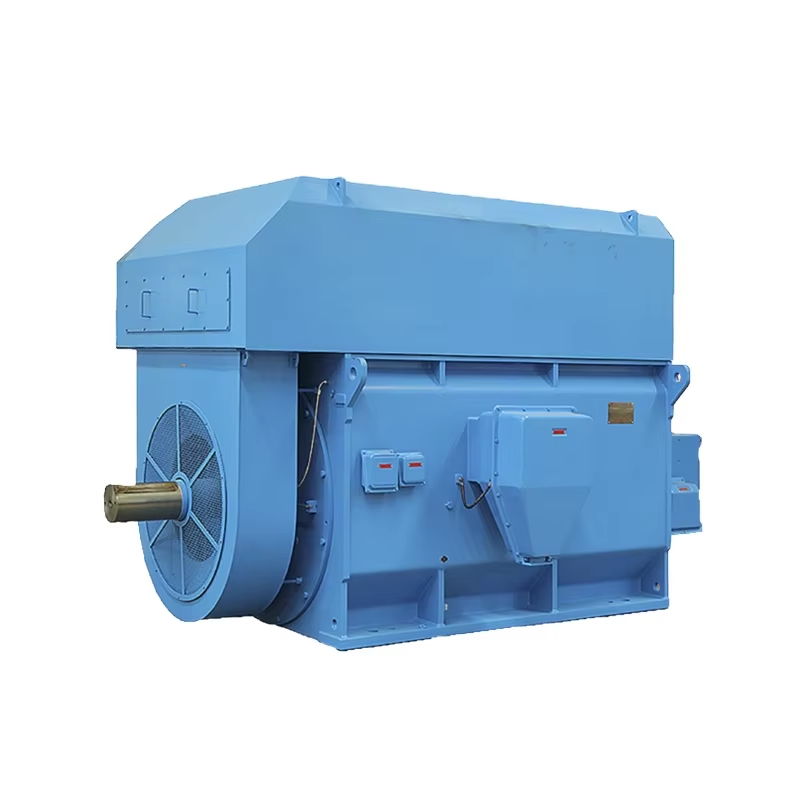

Wound rotor asynchronous motors (WRAMs) are commonly used in different sectors of industry for their effectiveness and flexibility. This research examines the working principles, maintenance approaches, and benefits of implementing WRAMs in modern machinery.

Comprehending Wound Rotor Asynchronous Motors

The squirrel cage rotor design is replaced by windings in the WRAM rotor. Such winding configuration increases motor speed and torque control, making WRAMs appropriate for variable speed operations. The functionality of WRAMs can be enhanced by varying slip through external resistance connections that brings the rotor windings to the external resistances. This added advantage makes it suitable in mining, cement, and metal processing industries where heavy loads along with fluctuating operational conditions are the norms.

Operational Efficiency and Advantages

Starting torque is critical for applications such as crushers and conveyors, systems employing WRAMs. External resistances tend to improve starting torque at the same time decreasing inrush current, resulting in lower electrical strain on the motor and its systems. Also, the broad operational speed range of WRAM facilitates multiple applications requiring speed distinguishment.

Maintenance Best Practices Procedures

As it is with every form of machinery, the winding rotor asynchronous motors will perform at their best and are most likely to last long if regular maintenance is conducted. These are the backbone practices which are very crucial:

-

Regular Inspections: Regular examination of electrical connections, rotor’s windings and bearings can bring forth some issues before there is a full fledged problem.

-

Lubrication: A correct amount of lubricant, and the right one too, used on the bearings can aid in combating wear and tear while drastically increasing the lifespan of the motor.

-

Cleaning: Cleaning the motor and any of its parts thoroughly from dust and debris can stop overheating.

Troubleshooting Common Issues

Ball bearing mounted WR asynchronous motors have proven to be robust devices. Though at times they can experience operational issues due to the following:

-

Insulation: Problems such as ground faults and short circuits stem from poorly insulated motors. Long term systematic insulation resistance tests can help bring out the deterioration.

-

Bearing Problems: Grinding sounds or excessive vibrations could be a sign of troublesome bearings. Strenuous bearing checks can mitigate these problems.

-

Electrical Volumes: Unbalance in the voltage supplied can establish imbalance in workings. Operating them without ensuring the voltage supplied is balanced, can lead to ruin.

Shifts in the Market and What’s Next

As more industries concentrate on energy conservation as well as sustainability, it is expected that the wound rotor asynchronous motors will see an increase in demand. Smarter and more efficient motors are already being developed because of technological advancements in motor design and control systems. Moreover, the inclusion of IoT technology in motor management systems will most likely improve predictive maintenance, which will reduce operational costs, downtime, and overall spend. WRAMs will continue to play a key role in a business’s productivity as industries evolve.

To conclude, businesses must keep best practices in maintenance and proactively stay informed on industry developments regarding motor-efficient technologies to maximize their operational efficiency. These strategies will help harness the operational flexibility and efficiency wound rotor asynchronous motors proudly claim.