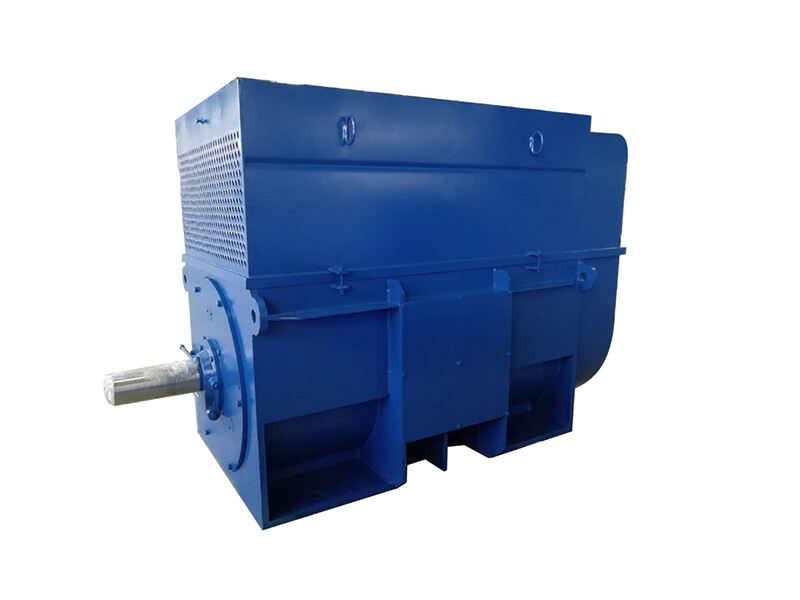

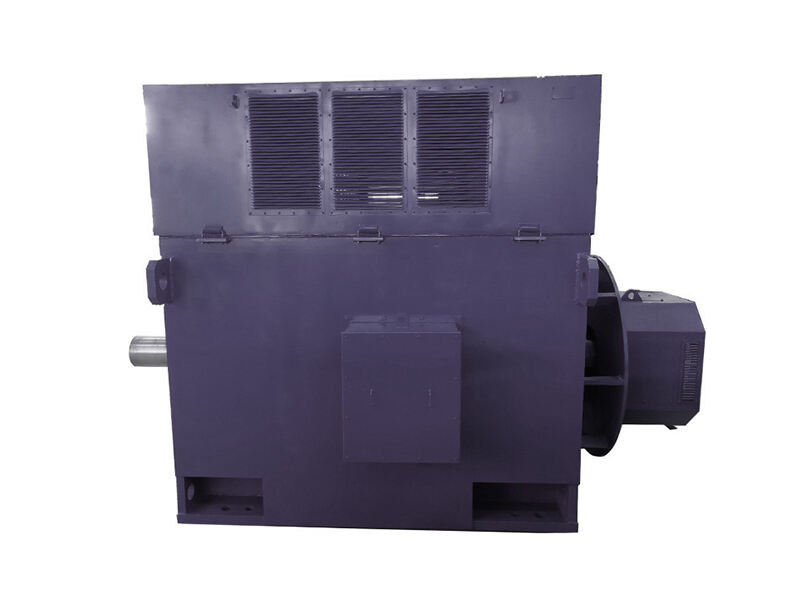

High voltage AC motors are essential in large scale woodworking facilities, powering heavy duty machinery used in processing logs into lumber, panels, and finished wood products. Operating at voltages between 3kV and 11kV, these motors deliver the high power, torque, and precise speed control required to handle the demanding conditions of woodworking, including high mechanical loads, dust, and variable material hardness. In woodworking facilities, high voltage AC motors drive primary breakdown equipment such as band saws and circular saws that cut logs into cants or lumber. These machines require high starting torque to overcome the resistance of cutting through dense hardwoods, with the motors’ robust design ensuring consistent performance even when encountering knots or uneven grain. Variable frequency drives (VFDs) allow for speed adjustments, enabling operators to optimize cutting speeds for different wood species, reducing waste and improving cut quality. High voltage AC motors also power planers and molders that shape lumber to precise dimensions, with their stable speed control ensuring uniform thickness and smooth surfaces. The motors’ low vibration operation minimizes chatter marks on wood, enhancing product quality. In panel production, these motors drive veneer dryers and presses that bond layers of wood to form plywood or particleboard, requiring reliable torque to maintain consistent pressure and heat distribution. Woodworking environments are characterized by high levels of sawdust and debris, so the motors feature dust tight enclosures (IP54 or higher) to prevent particulate ingress, which can cause bearing wear or electrical shorts. They also include efficient cooling systems to dissipate heat generated during continuous operation, with forced air ventilation that filters out dust to protect internal components. Insulation systems are rated for Class F to withstand elevated temperatures, ensuring long term reliability. High voltage AC motors power material handling systems such as conveyors and lifts that transport raw materials and finished products, with variable speed control enabling synchronization with production lines. Their high efficiency helps reduce energy consumption in woodworking facilities, where machinery operates for extended periods. Additionally, these motors drive sanding machines that finish wood surfaces, with precise speed control ensuring uniform sanding and reducing the risk of surface damage. By delivering reliable power, precise control, and durability in dusty environments, high voltage AC motors contribute to the efficiency and productivity of large scale woodworking operations.