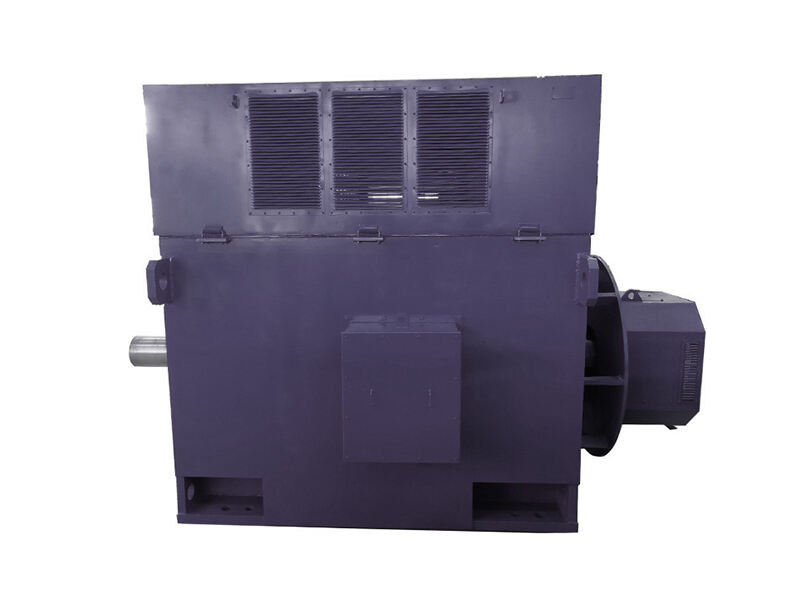

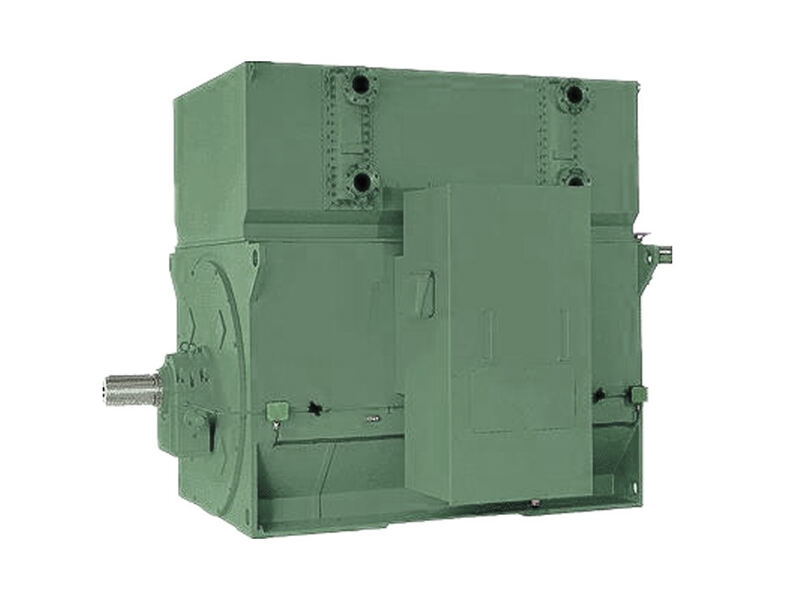

The reliability of high voltage AC motors in operation is a critical factor in ensuring the efficiency and safety of industrial processes across various sectors, including manufacturing, energy, mining, and chemical processing. Reliability in these motors is achieved through a combination of robust design, high quality materials, and advanced manufacturing processes. Key design features that enhance reliability include precision balanced rotors to minimize vibration, which reduces wear on bearings and other components, and high grade insulation systems that can withstand high temperatures, voltage stresses, and environmental contaminants. The use of premium materials, such as high strength steel for motor frames and copper for windings, ensures durability and long term performance. Advanced manufacturing techniques, including computer aided design and automated assembly, ensure consistency and precision in motor construction, reducing the risk of defects that could lead to failure. In operation, reliability is further enhanced by the integration of monitoring and diagnostic systems, such as thermal sensors, vibration analyzers, and current monitors, which provide real time data on motor performance. This allows for predictive maintenance, enabling operators to address potential issues before they escalate into failures. Regular maintenance practices, including lubrication, cleaning, and insulation testing, also play a vital role in maintaining reliability. By ensuring that high voltage AC motors operate consistently without unexpected downtime, industries can minimize production losses, reduce maintenance costs, and ensure the safety of personnel and equipment.