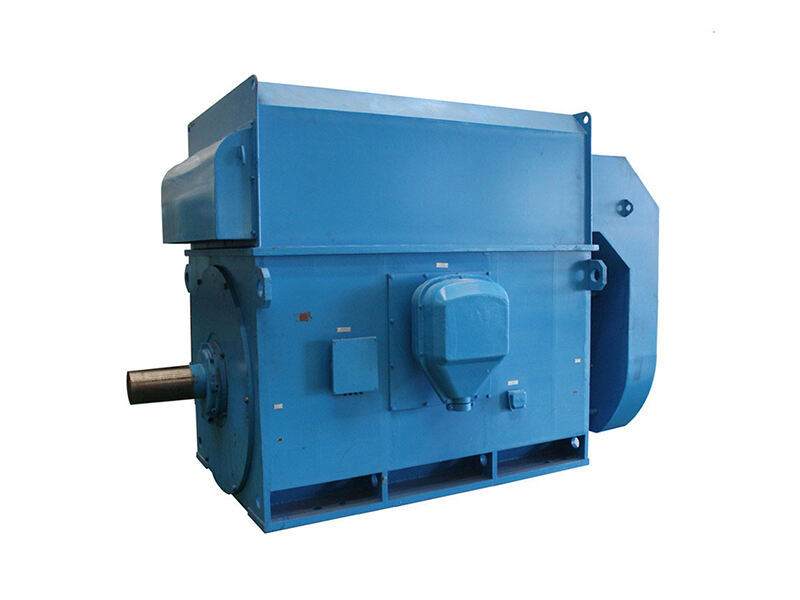

High voltage AC motors play a vital role in hydroelectric power plants, supporting both power generation and auxiliary operations in facilities that convert water energy into electricity. Operating at voltages typically between 6kV and 13.8kV, these motors are engineered to deliver reliable performance in the unique environment of hydroelectric facilities, which often involve high humidity, water exposure, and remote locations. A primary application is in pumped storage hydroelectric plants, where high voltage AC motors function as reversible machines—operating as motors to pump water from lower reservoirs to upper reservoirs during off peak hours and switching to generator mode to produce electricity during peak demand. These motors require high torque to drive large pumps against the gravitational force of water, with robust rotor and stator designs to handle cyclic loading and frequent mode transitions. Their ability to operate at variable speeds, controlled by advanced variable frequency drives (VFDs), optimizes pumping efficiency, reducing energy consumption during water transfer. In conventional hydroelectric plants, high voltage AC motors power essential auxiliary equipment, including intake gate operators, which control water flow into turbine chambers, and spillway gate motors, critical for managing water levels and preventing flooding. They also drive cooling water pumps that maintain optimal operating temperatures for generators and transformers, ensuring efficient power conversion. These motors are designed with corrosion resistant enclosures, often made from stainless steel or epoxy coated cast iron, to withstand the high humidity and potential water exposure in turbine halls and powerhouse areas. Insulation systems are specially formulated to resist moisture absorption, preventing electrical breakdown and ensuring long term reliability. High voltage AC motors in hydroelectric plants also drive ventilation systems that circulate air in generator rooms and equipment enclosures, controlling humidity and preventing condensation on electrical components. Their high efficiency minimizes auxiliary power consumption, which is crucial as hydroelectric plants aim to maximize net power output. Additionally, these motors are equipped with advanced monitoring systems to track vibration, temperature, and bearing condition, enabling predictive maintenance to reduce downtime in remote facilities where repairs can be logistically challenging. By delivering reliable power, efficient operation, and durability in aquatic environments, high voltage AC motors contribute to the sustainability and effectiveness of hydroelectric power generation, a key source of renewable energy.