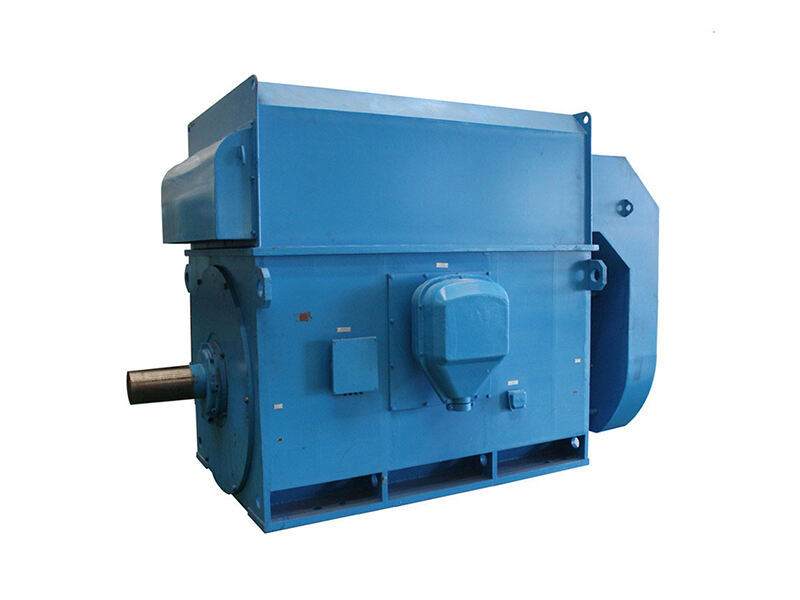

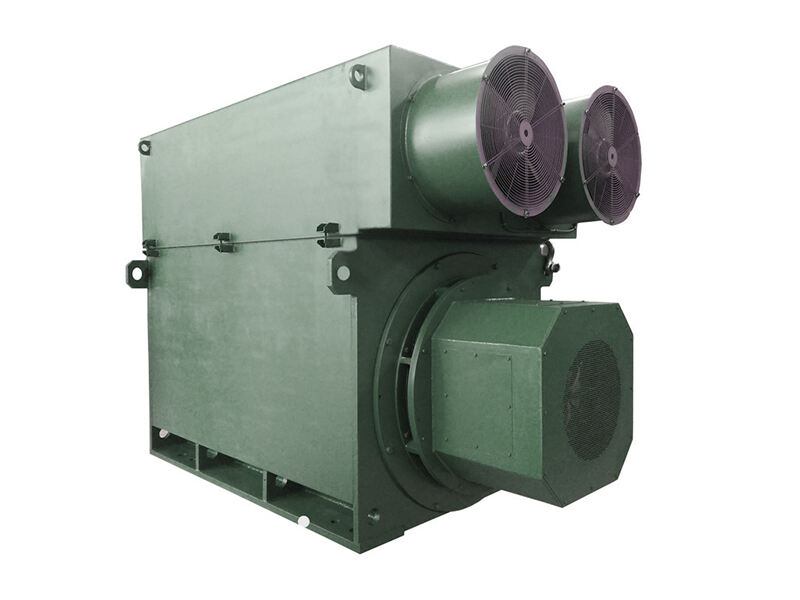

High voltage AC motors are the workhorses of large equipment across industrial sectors, providing the power, torque, and reliability required to operate heavy machinery in applications such as mining, construction, manufacturing, and energy production. Operating at voltages from 3kV to 13.8kV, these motors are engineered to drive large equipment with high power demands, often exceeding several megawatts, while delivering efficient performance under continuous or cyclic load conditions. In mining, high voltage AC motors power large excavators, draglines, and crushers, which handle massive volumes of ore and rock. These motors deliver high starting torque to overcome the inertia of heavy loads, with robust rotor and stator designs to withstand extreme vibration and dust exposure. Their ability to operate at variable speeds, controlled by VFDs, allows for precise adjustment of equipment operation—for example, matching crusher speed to ore hardness to optimize particle size and reduce energy consumption. In construction, they drive large cranes and concrete pumps, where reliable torque delivery ensures safe lifting of heavy loads and precise placement of materials. The motors’ compact design relative to their power output is advantageous in construction equipment, where space is limited. In manufacturing, high voltage AC motors power large industrial presses, rolling mills, and injection molding machines, requiring consistent torque to maintain product quality and production efficiency. These motors are designed with precision balanced components to minimize vibration, reducing wear on connected machinery and extending service life. They often feature liquid cooling systems to manage heat generated during high power operation, ensuring stable performance even in enclosed factory environments. Energy efficiency is a key attribute, with modern motors achieving IE3 or IE4 efficiency ratings, reducing operational costs for large equipment that operates continuously. The integration of smart monitoring systems allows for real time tracking of motor performance, including temperature, current, and vibration, enabling predictive maintenance to minimize downtime. Enclosures are tailored to application environments, with options for weatherproof, dust tight, or flameproof designs, ensuring durability in diverse conditions. By delivering high power, torque, and reliability, high voltage AC motors enable large equipment to operate efficiently, safely, and cost effectively, supporting productivity across critical industrial sectors.