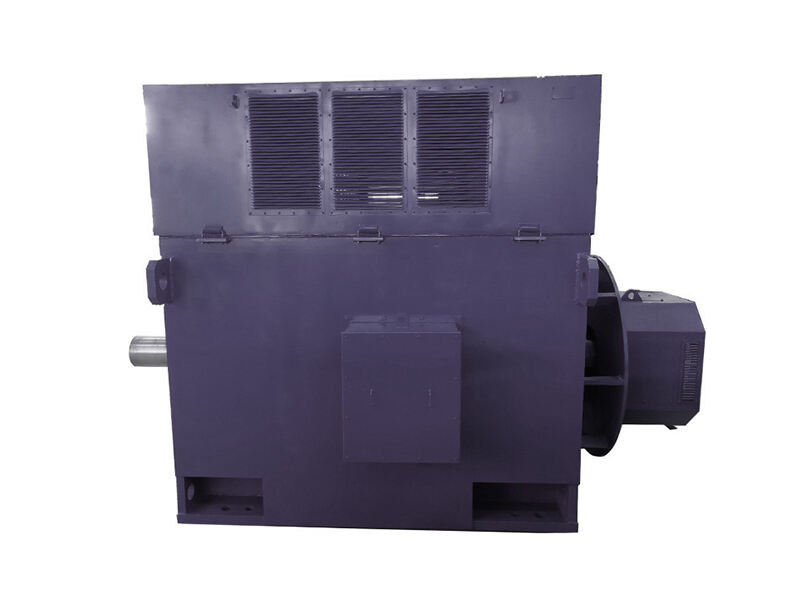

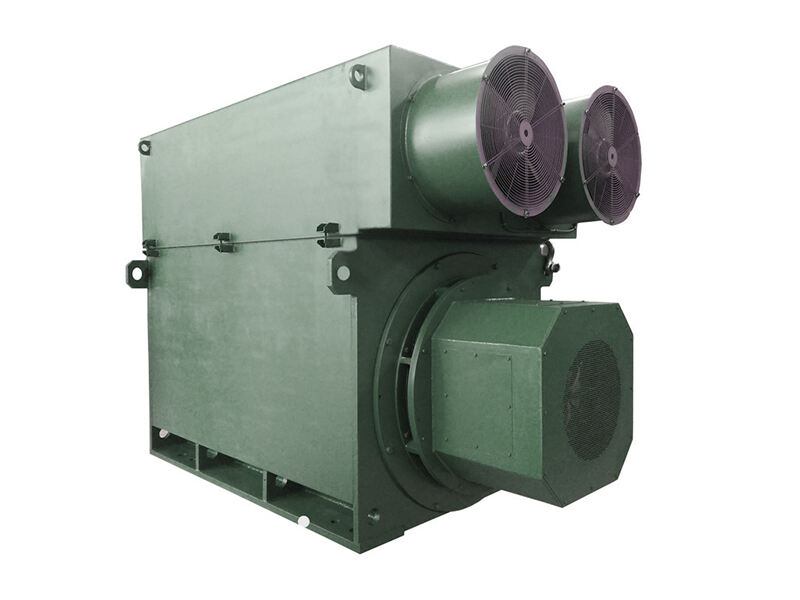

High voltage AC motors are integral to the operation of chemical plants, where they power a diverse array of equipment essential for chemical processing, mixing, pumping, and material handling. These motors, typically operating at voltages between 3kV and 11kV, provide the high power output required to drive large pumps, agitators, compressors, and conveyors used in the production of chemicals, pharmaceuticals, and petrochemicals. In chemical plant environments, which are often corrosive, humid, and potentially hazardous due to the presence of flammable or toxic substances, high voltage AC motors are designed with specialized features to ensure reliability and safety. This includes corrosion resistant coatings on motor enclosures, sealed bearings to prevent ingress of contaminants, and insulation systems that can withstand exposure to chemicals and high temperatures. The ability of these motors to operate at variable speeds, controlled by VFDs, allows for precise adjustment of process parameters, such as flow rates and mixing speeds, which is critical for maintaining product quality and optimizing reaction conditions. High voltage AC motors in chemical plants also contribute to energy efficiency, as their higher voltage rating reduces current flow, minimizing energy losses and lowering operating costs. Regular monitoring and maintenance, including thermal imaging and vibration analysis, help detect potential issues early, ensuring that these motors continue to operate safely and efficiently in the demanding conditions of chemical processing facilities.