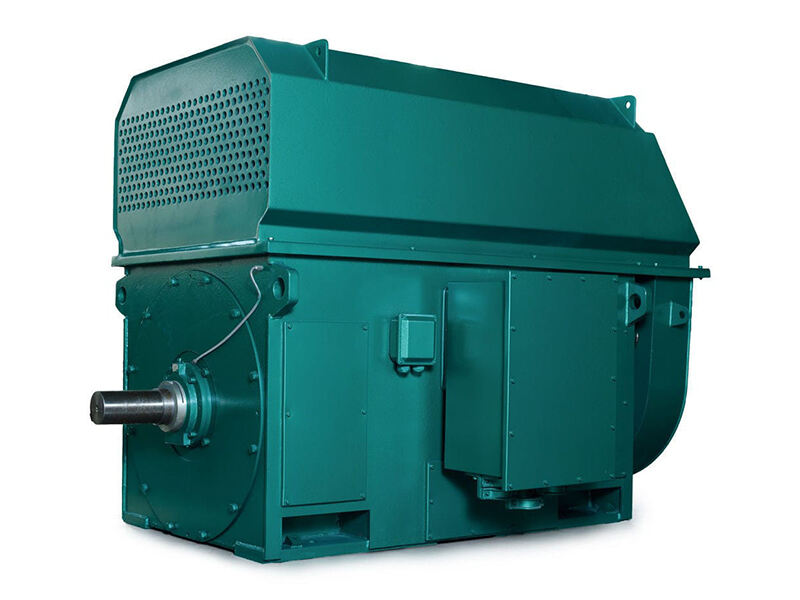

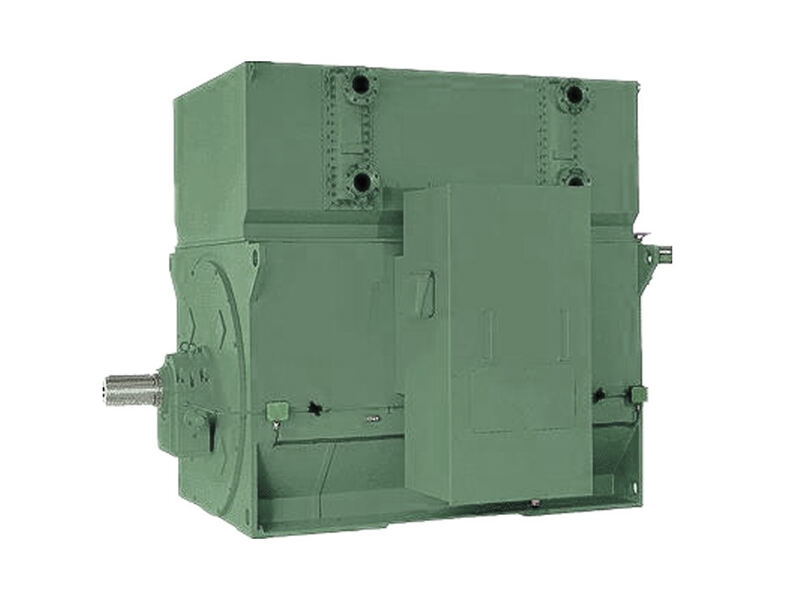

High voltage AC motors are indispensable in waste treatment plants, powering a diverse range of equipment involved in the collection, processing, and disposal of municipal, industrial, and hazardous waste. Operating at voltages between 3kV and 11kV, these motors deliver the high power, torque, and reliability required to handle the demanding conditions of waste treatment, including exposure to corrosive substances, high humidity, and abrasive particulate matter. In waste treatment plants, high voltage AC motors drive large pumps that transfer raw sewage, sludge, and treated effluent through various processing stages. These pumps often handle viscous, solids laden fluids, requiring motors with high starting torque to overcome initial resistance and maintain consistent flow rates. The motors’ robust construction includes corrosion resistant enclosures, typically made from stainless steel or epoxy coated cast iron, to withstand exposure to chemicals, acids, and biological contaminants present in waste streams. They also feature sealed bearings to prevent ingress of particulate matter, reducing wear and extending service life. High voltage AC motors power aeration systems that introduce oxygen into wastewater, facilitating the growth of microorganisms that break down organic pollutants. These systems use large blowers or compressors, where the motors’ variable speed control—enabled by VFDs—allows for precise adjustment of oxygen levels based on biological demand, optimizing treatment efficiency and reducing energy consumption. In sludge treatment processes, the motors drive centrifuges and dewatering equipment that separate solids from liquids, requiring high torque to process thick, dense sludge. Their ability to operate at varying speeds ensures efficient solids separation, with VFDs enabling fine tuning of process parameters for different sludge types. High voltage AC motors also power shredders and grinders that reduce the size of solid waste, preparing it for incineration, composting, or landfilling. These applications demand motors with rugged rotor and stator designs to withstand the impact and vibration of processing hard or bulky materials. Thermal management is critical, as waste treatment facilities often have high ambient temperatures; motors feature efficient cooling systems, such as forced air or liquid cooling, to maintain optimal operating temperatures. Insulation systems are rated for Class F or higher to resist heat and moisture, preventing electrical breakdown. Additionally, these motors drive conveyors that transport waste materials between processing stages, with reliable performance ensuring uninterrupted material flow. Advanced monitoring systems track motor performance, enabling predictive maintenance to minimize downtime in facilities where operational disruptions can lead to waste accumulation and environmental risks. By delivering reliable power, corrosion resistance, and efficient operation, high voltage AC motors play a vital role in ensuring the effectiveness and sustainability of waste treatment processes, protecting public health and the environment.