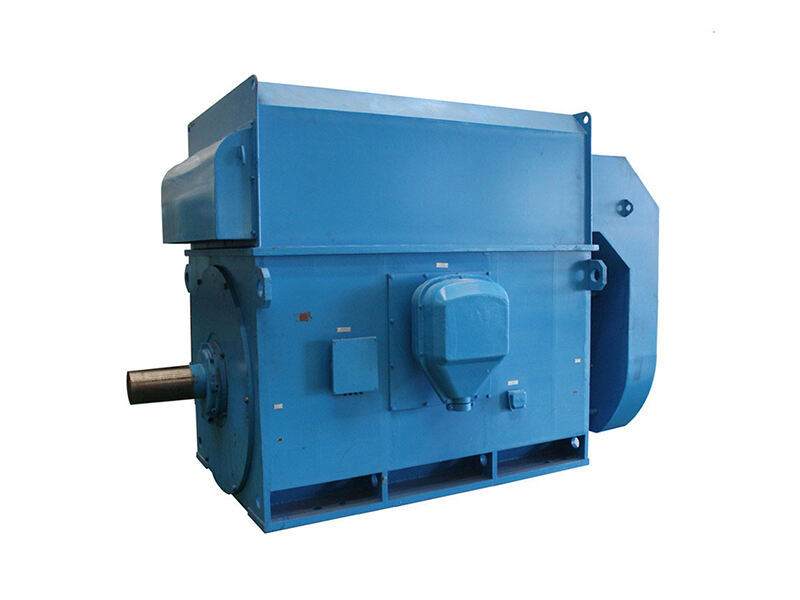

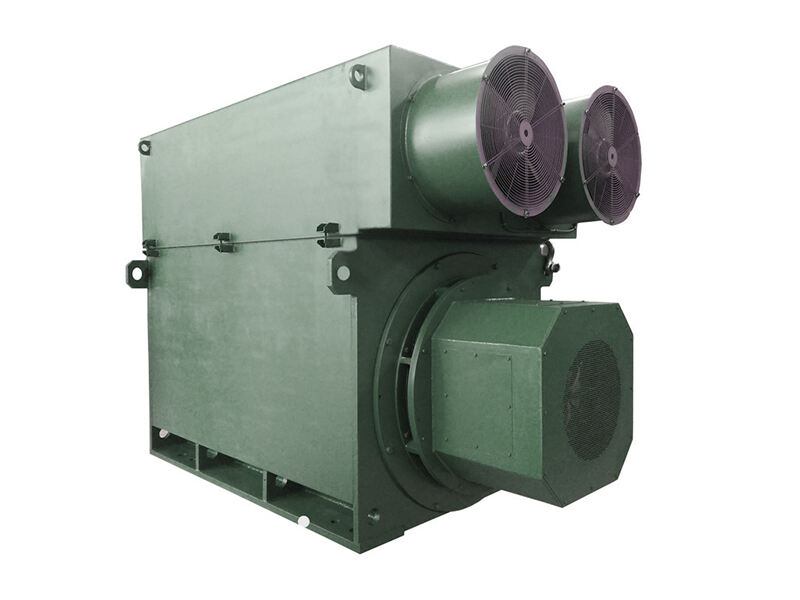

High voltage AC motors are widely used to power compressors in various industrial plants, including manufacturing facilities, refineries, and power generation plants, where compressed air or gas is essential for numerous processes. These motors, operating at voltages between 3kV and 11kV, provide the high power and consistent torque required to drive reciprocating, rotary screw, and centrifugal compressors efficiently. The performance of high voltage AC motors in compressor applications is characterized by their ability to maintain stable operation under varying load conditions, ensuring a continuous supply of compressed air or gas at the required pressure and flow rate. This stability is crucial for processes that depend on consistent compressed air, such as pneumatic tools, material handling, and process control systems. High voltage AC motors for compressors are designed with robust construction to withstand the high starting currents and cyclic loads associated with compressor operation. They feature high quality bearings and insulation systems capable of handling the thermal and mechanical stresses generated during continuous operation. The integration of VFDs with these motors allows for precise speed control, enabling compressors to adjust their output based on demand, which significantly improves energy efficiency and reduces operating costs. Additionally, these motors are often equipped with advanced monitoring systems that track parameters such as temperature, vibration, and current, enabling predictive maintenance and minimizing the risk of unexpected failures that could disrupt plant operations.