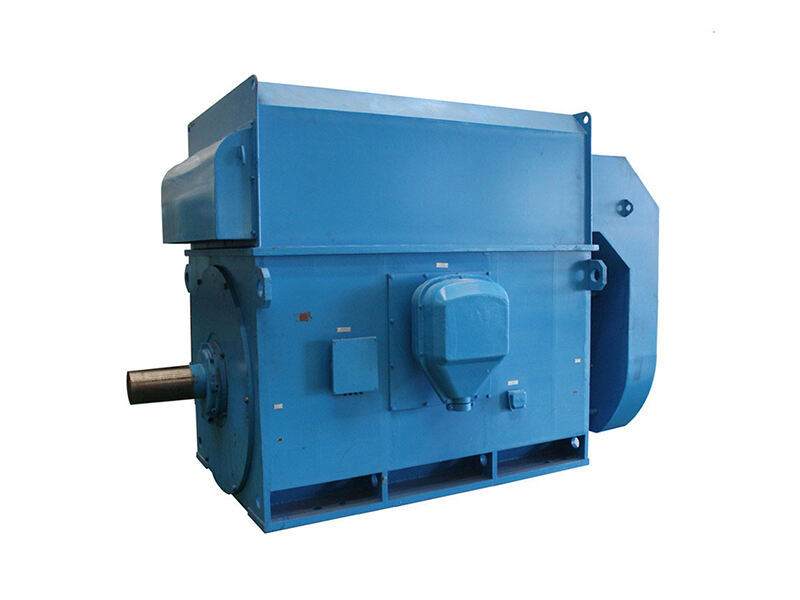

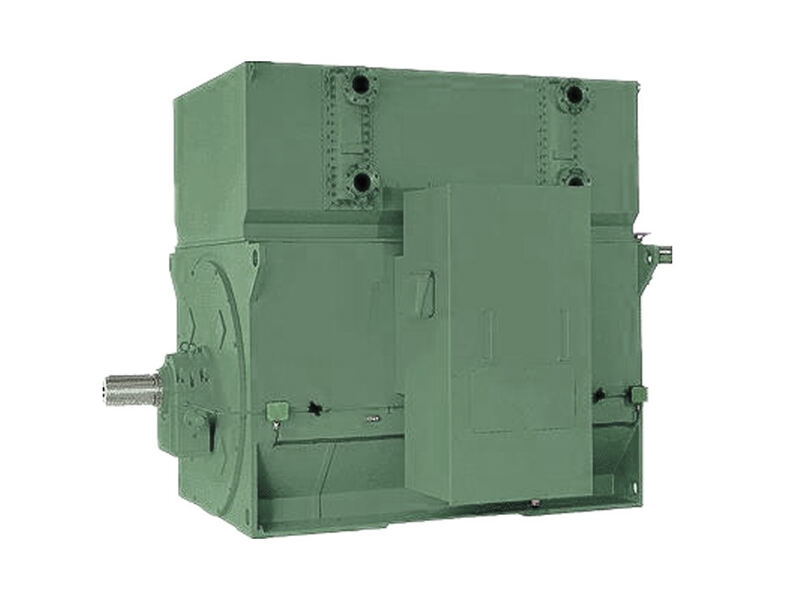

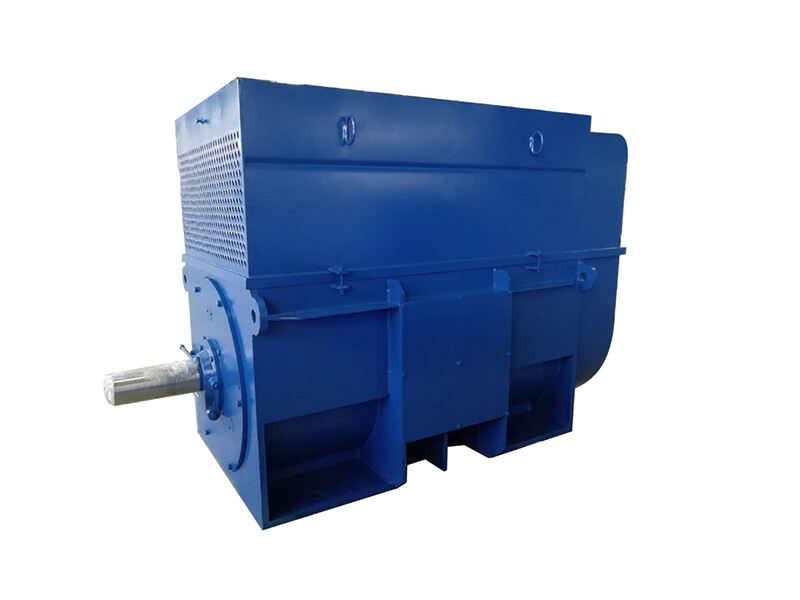

High voltage AC motors are increasingly becoming the preferred choice for powering large and heavy duty machine tools in industrial manufacturing, including lathes, milling machines, grinders, and machining centers. These motors, operating at voltages from 3kV to 11kV, deliver the high torque and power required to handle heavy workpieces and perform precision machining operations. The use of high voltage AC motors in machine tools offers several advantages, including improved power density, which allows for more compact motor designs without sacrificing performance. This is particularly beneficial in machine tool applications where space is often limited. The ability to operate at variable speeds, controlled by advanced VFDs, enables precise speed regulation, which is essential for achieving accurate machining results across different materials and cutting operations. High voltage AC motors for machine tools are designed with rigid construction to minimize vibration, ensuring stable operation and reducing tool wear, which in turn improves the quality of machined parts. They also feature efficient cooling systems, such as forced air or liquid cooling, to maintain optimal operating temperatures during prolonged machining sessions. Additionally, these motors offer high efficiency, reducing energy consumption and lowering operational costs for manufacturing facilities. Their reliability is critical to minimizing downtime in production environments, ensuring that machine tools can operate continuously to meet production deadlines and maintain high levels of productivity.