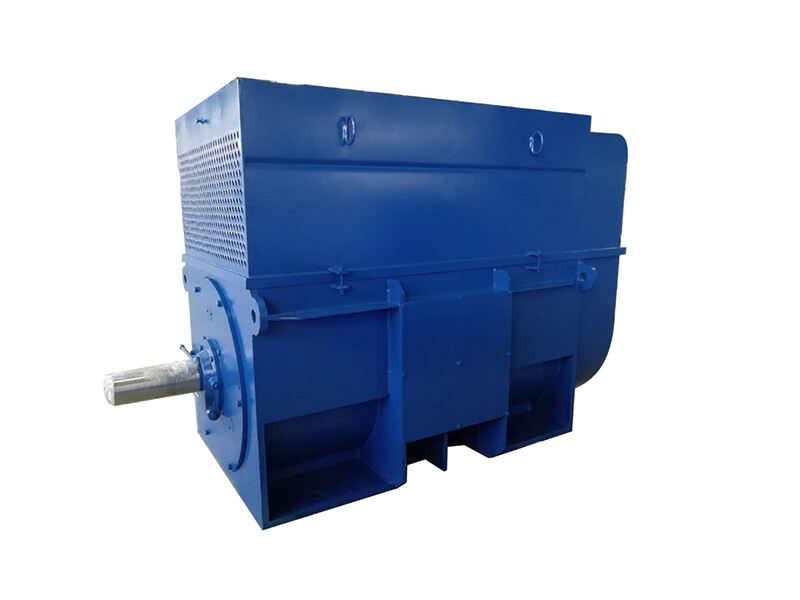

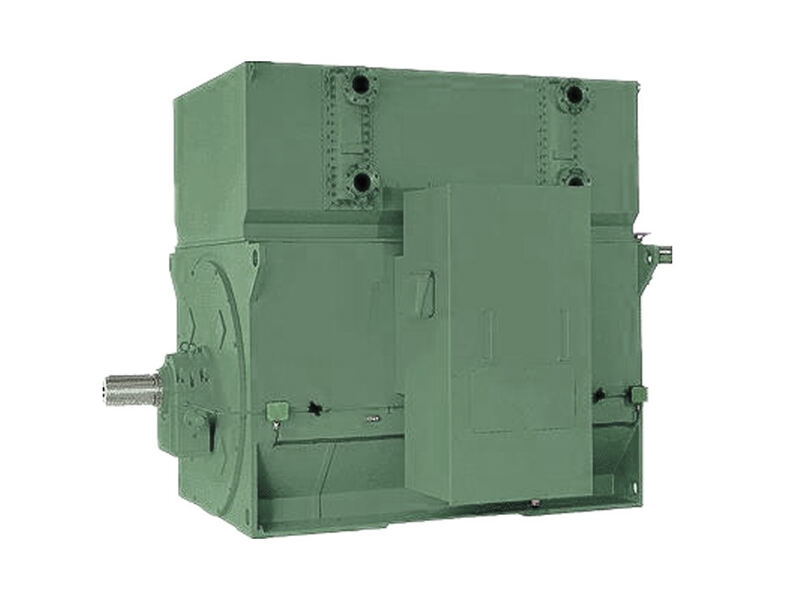

Chinese manufacturers of high voltage AC motors have emerged as global leaders, combining advanced engineering, cost competitiveness, and adherence to international standards to serve diverse industrial markets, including energy, manufacturing, mining, and infrastructure. These manufacturers, such as Siemens (China), ABB (China), WEG (China), and domestic firms like Shanghai Electric, Harbin Electric, and Xiangtan Electric, produce motors ranging from 3kV to 13.8kV, with power ratings from hundreds to thousands of kilowatts, tailored to applications like pumps, compressors, and heavy machinery. A key strength of Chinese high voltage AC motor manufacturers is their integration of global technology with localized production capabilities. Many partner with international firms to adopt cutting edge designs, such as efficient stator and rotor configurations, high grade insulation materials (e.g., Nomex® for Class F/H insulation), and precision manufacturing processes. This ensures their motors meet stringent standards, including IEC, IEEE, ATEX, and GB (Chinese national standards), making them suitable for export to regions like Europe, Southeast Asia, and the Americas. Cost efficiency is another hallmark, driven by economies of scale, a robust supply chain for raw materials (e.g., electrical steel, copper), and skilled labor. This allows Chinese manufacturers to offer competitive pricing without compromising quality, appealing to industries seeking to balance performance and budget. Innovation is a priority, with significant investments in research and development (R&D) to enhance motor efficiency—many models achieve IE3 or IE4 efficiency ratings, aligning with global energy conservation goals. Manufacturers also focus on customization, offering motors with features like flameproof enclosures for hazardous environments, corrosion resistant coatings for chemical applications, and integration with VFDs for variable speed control. Production facilities are equipped with advanced testing equipment, including dynamometers for performance testing, thermal imaging systems for insulation checks, and vibration analyzers to ensure reliability. Quality control processes adhere to ISO 9001 standards, with rigorous inspections at every stage—from material sourcing to final assembly. Chinese manufacturers also emphasize after sales support, providing technical assistance, maintenance services, and spare parts to global clients, ensuring long term customer satisfaction. In recent years, they have expanded their focus on sustainability, developing motors with reduced carbon footprints, using recyclable materials, and optimizing production processes to minimize energy use. This commitment to quality, innovation, and global compliance has positioned Chinese high voltage AC motor manufacturers as trusted partners in industrial electrification, catering to the evolving needs of a diverse, international clientele.