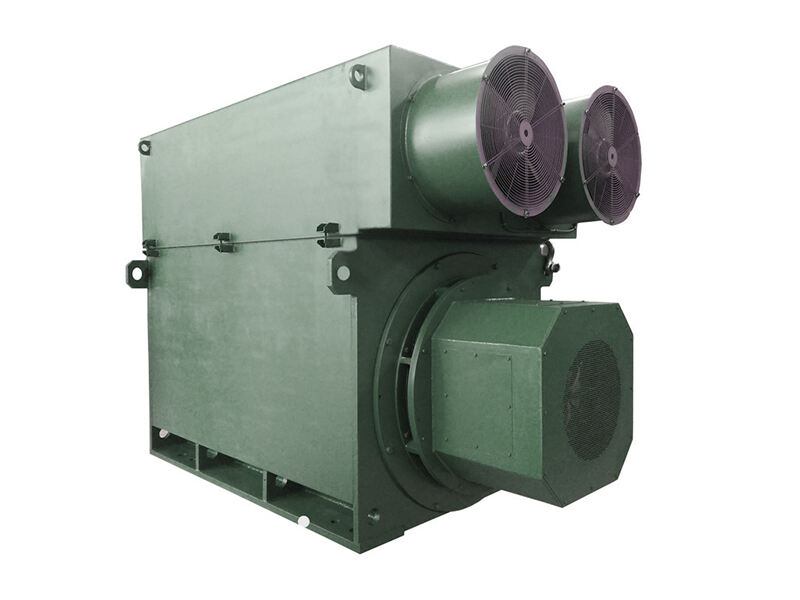

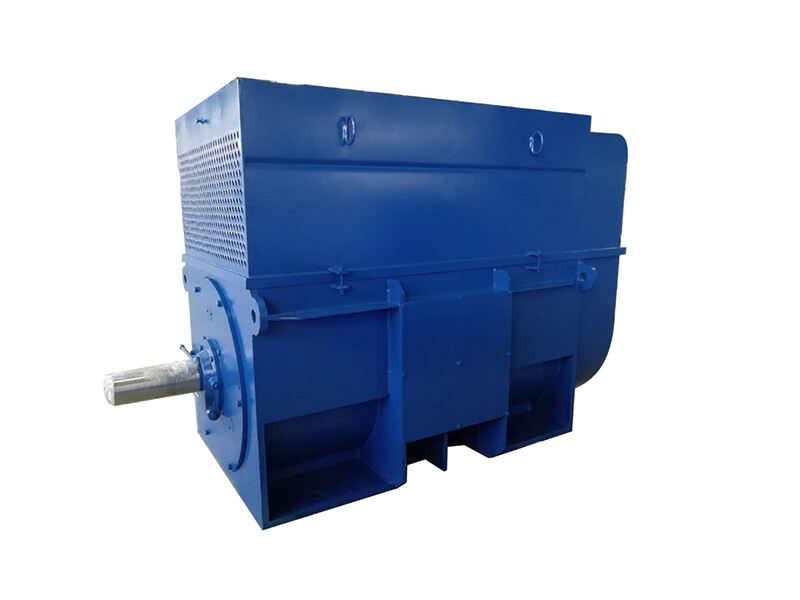

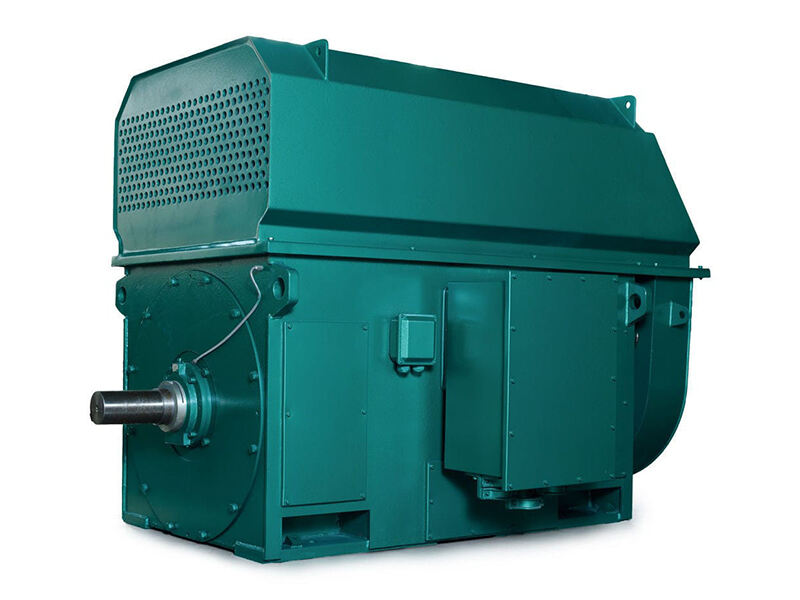

High voltage AC motors are vital in the oil and gas industry, powering critical equipment across exploration, production, refining, and transportation operations. Operating at voltages typically between 6kV and 13.8kV, these motors are engineered to withstand extreme conditions, including high pressures, corrosive environments, and hazardous atmospheres where flammable gases or vapors are present. In upstream oil and gas operations, high voltage AC motors drive pumps and compressors in offshore platforms and onshore wells, extracting hydrocarbons from reservoirs. These motors must deliver high torque to operate submersible pumps that lift crude oil or natural gas from deep underground, often under high pressure. Their flameproof enclosures, compliant with ATEX and IECEx standards, prevent ignition of flammable gases, with machined flame paths that contain internal explosions. In midstream operations, high voltage AC motors power pipeline compressors that transport natural gas over long distances, maintaining pressure to ensure continuous flow. Variable frequency drives (VFDs) enable precise speed control, optimizing compressor efficiency and reducing energy consumption. These motors are designed to operate continuously in remote locations, with robust construction featuring heavy duty bearings and corrosion resistant materials to withstand exposure to weather and saltwater in coastal or offshore installations. In downstream refining, high voltage AC motors drive pumps that transfer crude oil and refined products between processing units, as well as mixers and agitators in distillation and catalytic cracking processes. They must resist exposure to corrosive chemicals and high temperatures, with insulation systems rated for Class F or higher and enclosures protected by epoxy coatings or stainless steel. High voltage AC motors also power cooling tower fans and boiler feed pumps in refineries, ensuring efficient heat removal and steam generation. Their reliability is critical, as unplanned downtime in refining can result in significant production losses. Advanced monitoring systems, including vibration and temperature sensors, enable remote condition monitoring, allowing for predictive maintenance to address issues before they cause failures. Additionally, these motors drive offshore crane systems used for equipment handling and maintenance, requiring precise speed control and high lifting torque. By combining hazardous area certification, corrosion resistance, high efficiency, and reliable performance, high voltage AC motors play a crucial role in ensuring the safety, productivity, and efficiency of oil and gas operations.