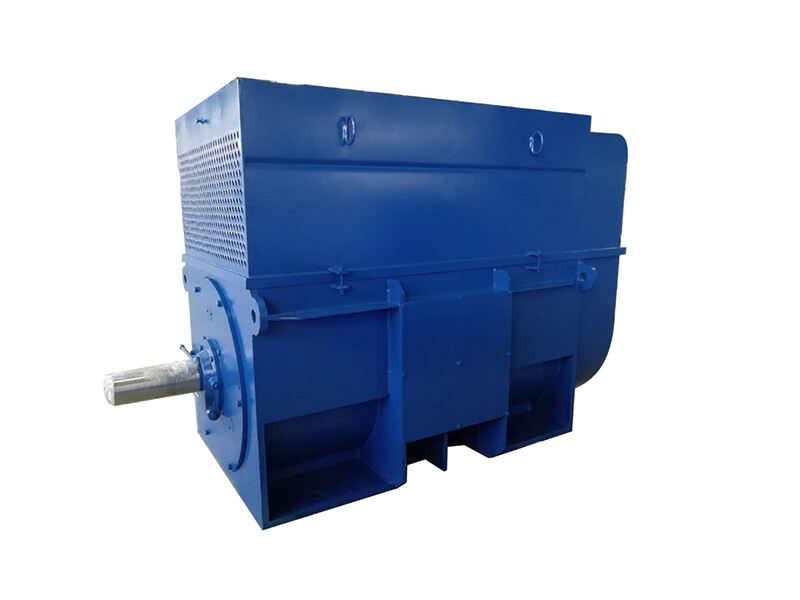

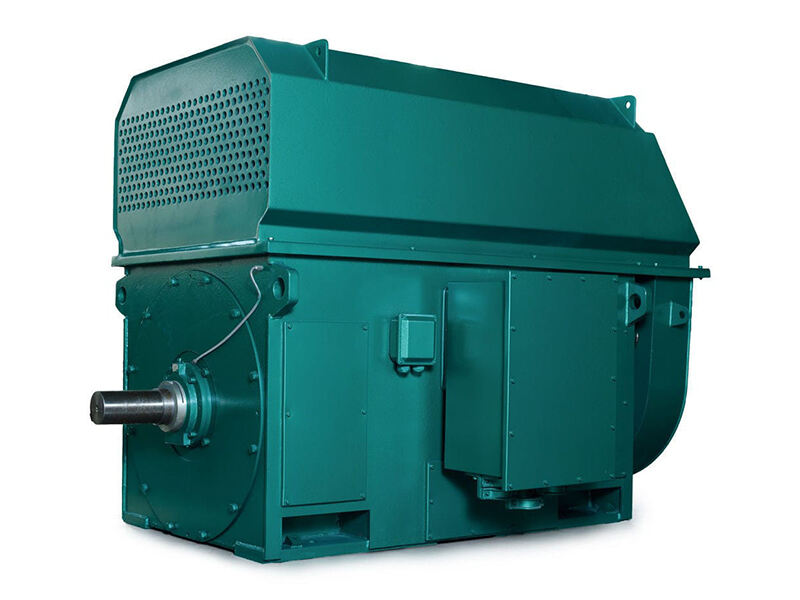

High voltage AC motors are critical components in the rubber and plastics industry, powering a wide range of machinery involved in the production of rubber products, plastic resins, films, and molded parts. Operating at voltages between 3kV and 11kV, these motors deliver the high power, torque, and precise speed control required to handle the demanding processes of melting, mixing, extruding, and shaping polymeric materials. In rubber processing, high voltage AC motors drive internal mixers and banbury mixers that combine rubber compounds with additives, fillers, and curing agents. These mixers require high torque to handle the viscous, high friction mixing process, with the motors’ robust rotor designs ensuring consistent performance even under heavy loads. Variable frequency drives (VFDs) enable precise speed adjustments, allowing operators to control mixing intensity and duration, critical factors in achieving uniform material properties. In plastics extrusion, high voltage AC motors power screw extruders that melt and shape plastic resins into profiles, pipes, or films. The motors’ precise speed control ensures consistent screw rotation, which is essential for maintaining uniform melt flow and product dimensions. Their ability to maintain stable torque prevents fluctuations in extrusion pressure, reducing defects such as 厚薄不均 or surface imperfections. High voltage AC motors also drive injection molding machines that produce complex plastic parts, requiring rapid acceleration and deceleration to control the injection and clamping phases. Their high starting torque ensures reliable operation of hydraulic pumps that generate clamping force, often exceeding thousands of kilonewtons. These motors are designed to withstand the high ambient temperatures in processing areas, where molten plastics can raise temperatures above 40°C, with efficient cooling systems and Class F insulation to prevent overheating. They must also resist exposure to dust from plastic pellets and volatile organic compounds (VOCs) released during processing, with sealed enclosures and chemical resistant coatings. In rubber vulcanization, high voltage AC motors power presses that shape and cure rubber products under heat and pressure, with precise speed control ensuring accurate timing of the curing cycle. Their high efficiency helps reduce energy consumption in the energy intensive plastics and rubber industry, aligning with sustainability goals. Advanced monitoring systems track motor performance, enabling predictive maintenance to minimize downtime in continuous production environments. By delivering reliable power, precise control, and durability, high voltage AC motors play a vital role in ensuring the quality and efficiency of rubber and plastics manufacturing processes.