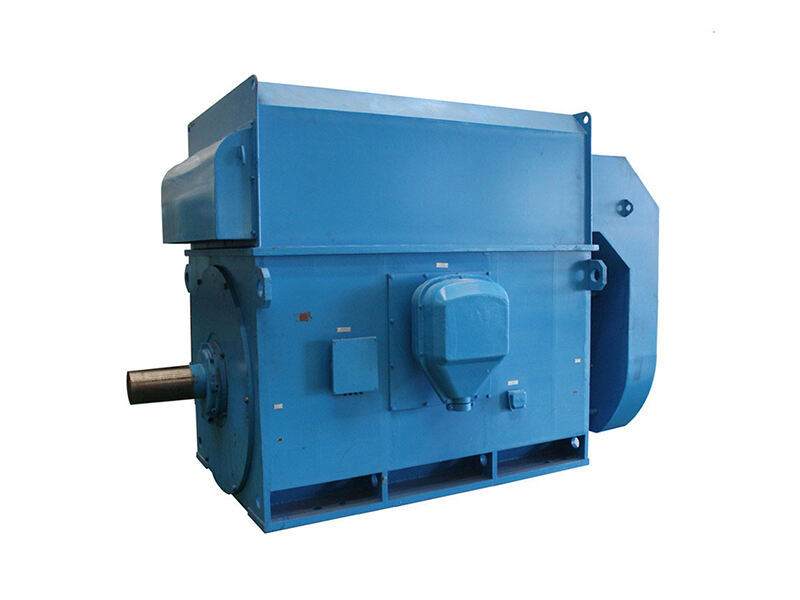

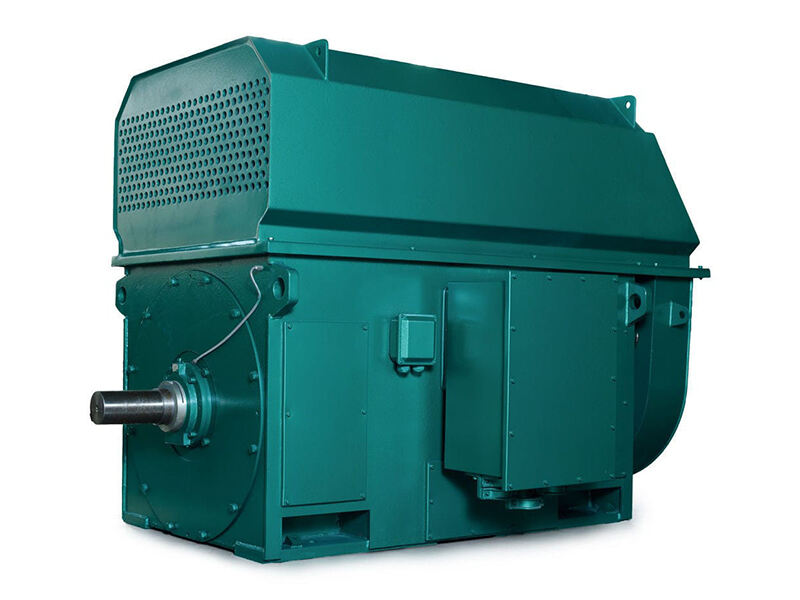

High voltage AC motors, often integrated as generators, are central components in wind turbines, converting rotational energy from turbine blades into electrical power for grid distribution. Operating at voltages typically between 6kV and 33kV, these motors (or generators) are engineered to withstand the unique challenges of wind energy applications, including variable wind speeds, cyclic loading, and exposure to harsh environmental conditions such as extreme temperatures, humidity, and vibration. In modern wind turbines, high voltage AC synchronous or asynchronous generators are commonly used, with synchronous generators offering higher efficiency and better grid compatibility. These motors generate alternating current at variable frequencies, which is converted to fixed frequency AC using power converters, enabling integration with the electrical grid. The high voltage design reduces current levels, minimizing energy losses in power transmission from the turbine nacelle to grid transformers, especially in large turbines with capacities exceeding 4MW. Wind turbine motors must deliver reliable performance under fluctuating loads, as wind speeds vary continuously. Their robust construction includes reinforced rotor assemblies with high strength magnets (in permanent magnet synchronous generators) or wound rotors (in doubly fed induction generators) to handle dynamic stresses from blade rotation. Bearings are designed for extended service intervals, often up to 20 years, with advanced lubrication systems to withstand continuous operation. The nacelle, housing the motor, features weatherproof enclosures with thermal management systems air or liquid cooling to maintain optimal operating temperatures, even in extreme climates ranging from 40°C to 50°C. Insulation systems are specially formulated to resist moisture, UV radiation, and corrosion, ensuring electrical integrity over the turbine’s lifespan. Additionally, these motors incorporate condition monitoring systems with sensors for vibration, temperature, and magnetic flux, enabling remote diagnostics to detect potential issues such as bearing wear or insulation degradation. This predictive maintenance capability is crucial for reducing downtime in offshore or remote wind farms, where access is challenging and costly. By combining high efficiency, durability, and grid compatibility, high voltage AC motors enable wind turbines to maximize power output, contributing to the growth of renewable energy and the transition to sustainable electricity generation.