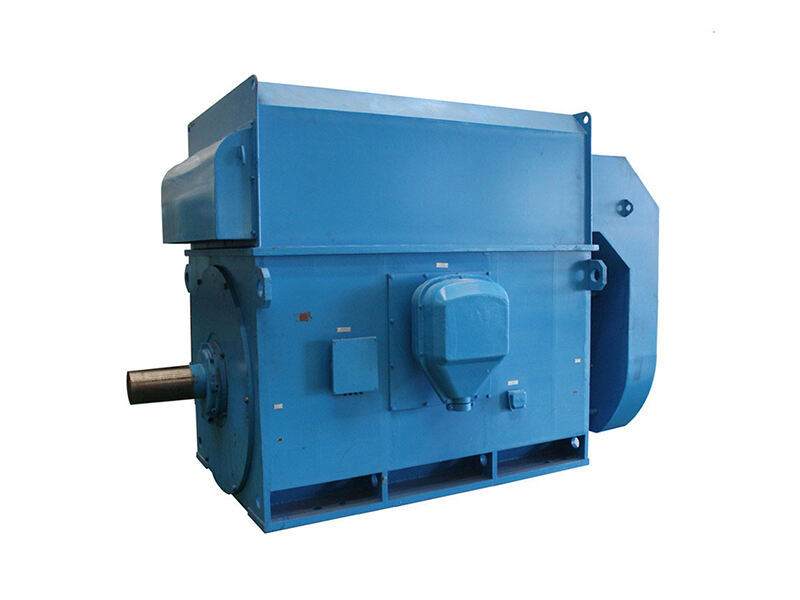

High voltage AC motors are essential components in geothermal power plants, where they support critical operations involved in converting heat from the Earth’s crust into electricity. Operating at voltages typically between 6kV and 13.8kV, these motors are engineered to withstand the unique challenges of geothermal environments, including high temperatures, corrosive gases, and mineral rich fluids. In geothermal power plants, high voltage AC motors primarily drive pumps that circulate geothermal fluids, such as brine, from underground reservoirs to the surface. These fluids often contain dissolved solids, sulfur compounds, and corrosive gases like hydrogen sulfide, requiring motors with robust, corrosion resistant enclosures—typically made from stainless steel or nickel alloys—to prevent degradation. The pumps must operate continuously under high pressure, making the motors’ high torque output and reliability paramount. High voltage AC motors deliver the necessary starting torque to overcome the initial resistance of pumping dense, mineral laden fluids, ensuring consistent flow rates essential for efficient heat exchange. They also power auxiliary equipment, including fan driven cooling towers that condense steam after it passes through turbines, with variable frequency drives (VFDs) enabling precise speed control to optimize cooling efficiency based on ambient conditions. Thermal management is a critical design consideration, as geothermal power plants operate in high temperature environments, often exceeding 40°C. Motors feature advanced cooling systems, such as liquid cooled jackets or forced air ventilation with heat resistant materials, to maintain optimal operating temperatures and prevent insulation breakdown. Insulation systems are specially formulated to resist thermal aging and degradation from exposure to corrosive vapors, often utilizing Class H or higher insulation rated for temperatures up to 180°C. Additionally, these motors drive water treatment pumps that process geothermal fluids to remove minerals, preventing scaling and fouling in pipes and equipment. Their high efficiency minimizes auxiliary power consumption, which is crucial for maximizing the net power output of geothermal plants. Condition monitoring systems, including sensors for vibration, temperature, and bearing wear, enable predictive maintenance to detect issues early, reducing downtime in facilities where repairs can be complicated by the harsh environment. By combining durability, corrosion resistance, and reliable performance, high voltage AC motors contribute to the efficiency and sustainability of geothermal power generation, a renewable energy source with minimal carbon emissions.