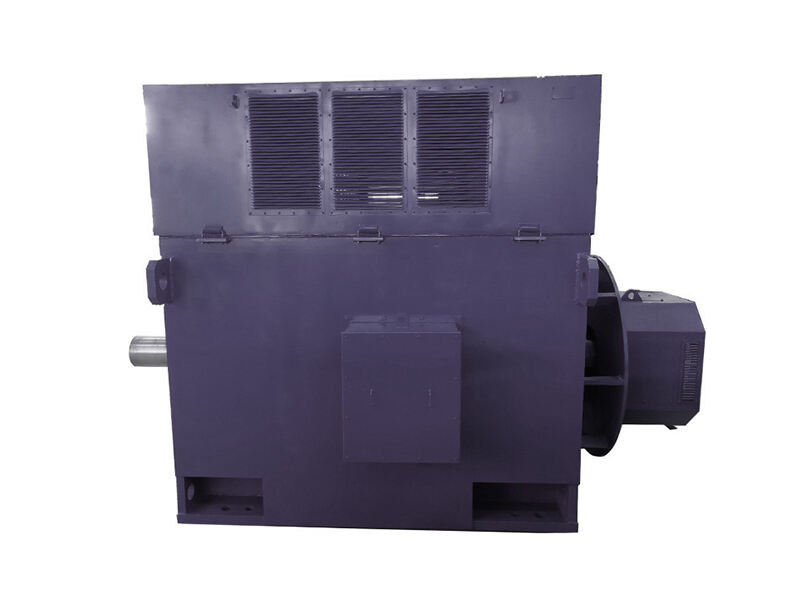

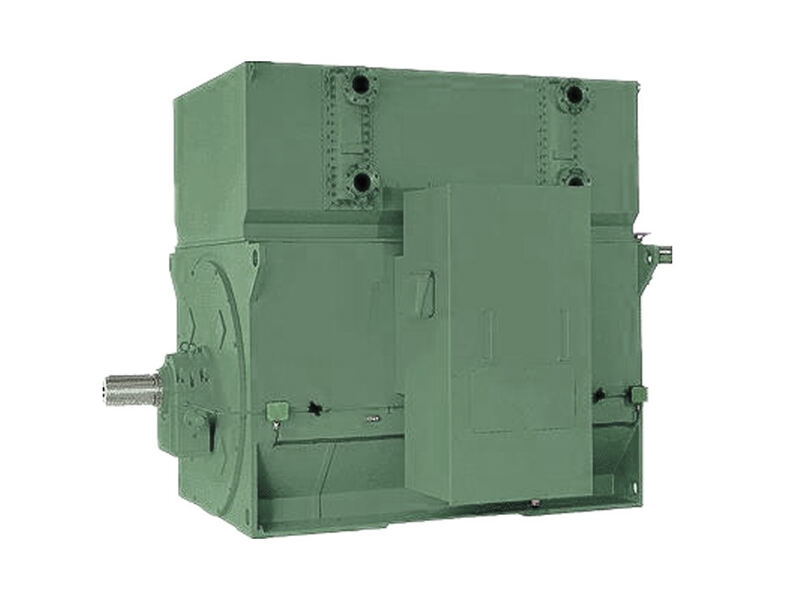

High voltage AC motors are integral to powering pumps in factories across diverse industries, including manufacturing, chemical processing, and wastewater management, where fluid transfer is a core operational requirement. These motors, typically operating at voltages ranging from 3kV to 11kV, deliver the robust power and consistent torque needed to drive centrifugal, reciprocating, and diaphragm pumps efficiently, ensuring the seamless movement of liquids such as water, chemicals, oils, and slurries. In factory settings, pumps often operate continuously under varying load conditions, making the reliability of high voltage AC motors paramount. Their design incorporates features like heavy duty bearings to withstand prolonged rotational stress, high grade insulation systems resistant to thermal degradation, and robust enclosures that protect internal components from dust, moisture, and industrial contaminants. The integration of variable frequency drives (VFDs) with these motors allows for precise control of pump speed, enabling factories to adjust flow rates according to real time demand. This not only optimizes energy consumption—reducing operational costs by minimizing unnecessary power usage during low demand periods—but also reduces mechanical wear on pump components, extending their service life. High voltage AC motors for factory pumps also contribute to system safety through built in protection mechanisms, such as overload relays, temperature sensors, and fault detection systems, which prevent motor damage and ensure uninterrupted operation. Whether used in cooling systems, boiler feed pumps, or process fluid transfer, these motors are engineered to meet strict industrial standards, ensuring compatibility with diverse pump types and factory infrastructure while maintaining high efficiency and durability in the demanding environments of modern manufacturing facilities.