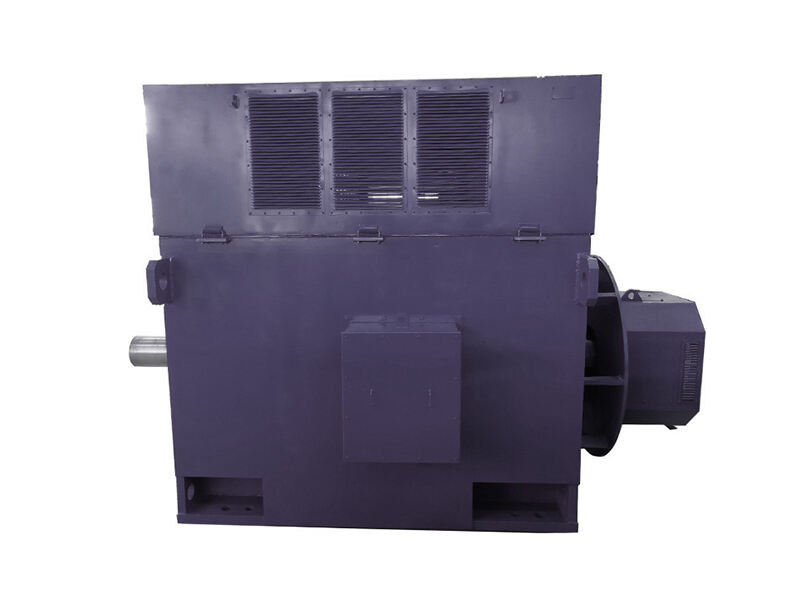

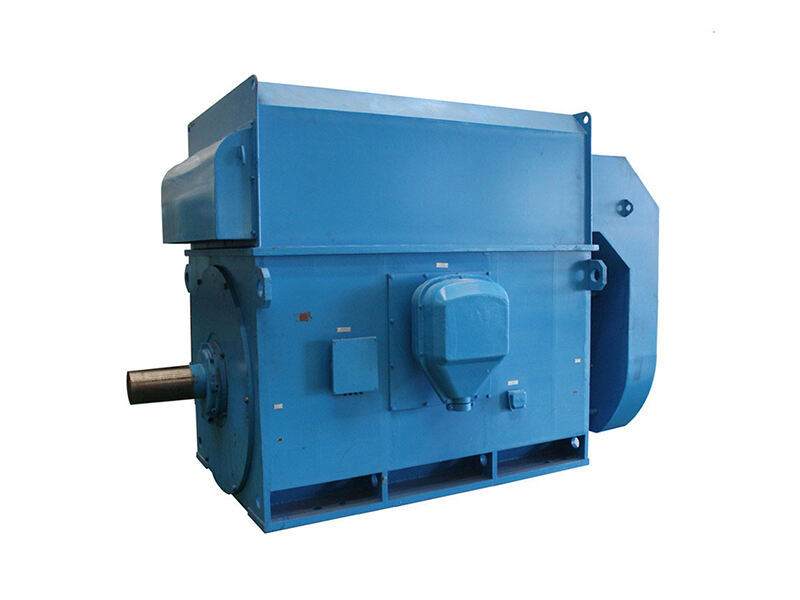

High voltage AC motors play a dual role in power generation facilities, serving as both prime movers in pumped storage hydroelectric systems and auxiliary drives for critical equipment like boiler feed pumps, fans, and coal conveyors in thermal power plants. Operating at voltages typically between 6kV and 13.8kV, these motors deliver the high power and reliability required to support the continuous, efficient operation of power generation infrastructure, where downtime can have far reaching consequences for energy supply. In pumped storage systems—used to store excess electricity by pumping water to elevated reservoirs for later use—high voltage AC motors act as reversible machines, functioning as motors to drive pumps during off peak hours and as generators to produce electricity during peak demand. These motors require exceptional torque to lift large volumes of water against gravitational forces, often operating at high speeds (up to 3600 RPM) with rapid switching between motor and generator modes. Their design includes robust rotor assemblies with high mechanical strength to withstand cyclic loads, and insulation systems capable of handling voltage fluctuations during mode transitions. In thermal power plants (coal, gas, or nuclear), high voltage AC motors power auxiliary systems essential for electricity production. Boiler feed pumps, which supply water to high pressure boilers, rely on these motors to deliver consistent flow rates under extreme pressure—often exceeding 100 bar. The motors’ high efficiency minimizes energy loss, a critical factor since auxiliary systems can consume up to 5% of a plant’s total output. Fans, used for combustion air supply and flue gas extraction, depend on precise speed control (via VFDs) to optimize fuel combustion and emissions, with motors engineered to resist high temperatures and corrosive flue gases. High voltage AC motors in power generation are designed for long term reliability, with features like heavy duty bearings lubricated for extended service intervals, enclosed cooling systems (air or water cooled) to maintain optimal operating temperatures, and redundant protection mechanisms (overload, overvoltage, and short circuit protection) to prevent damage during electrical faults. They also adhere to strict standards, such as IEEE 841 for severe duty motors, ensuring compatibility with power plant infrastructure. In renewable energy, such as biomass or concentrated solar power plants, these motors drive material handling equipment and heat transfer systems, contributing to the integration of clean energy sources. Their ability to operate in grid connected or standalone modes makes them versatile in hybrid power systems. Overall, high voltage AC motors are indispensable in power generation, enabling efficient, reliable, and sustainable electricity production across diverse energy sources.