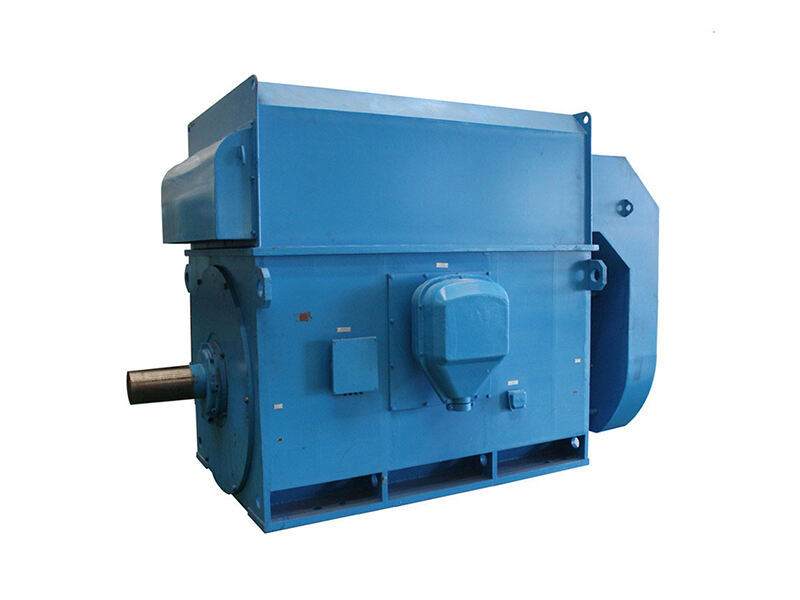

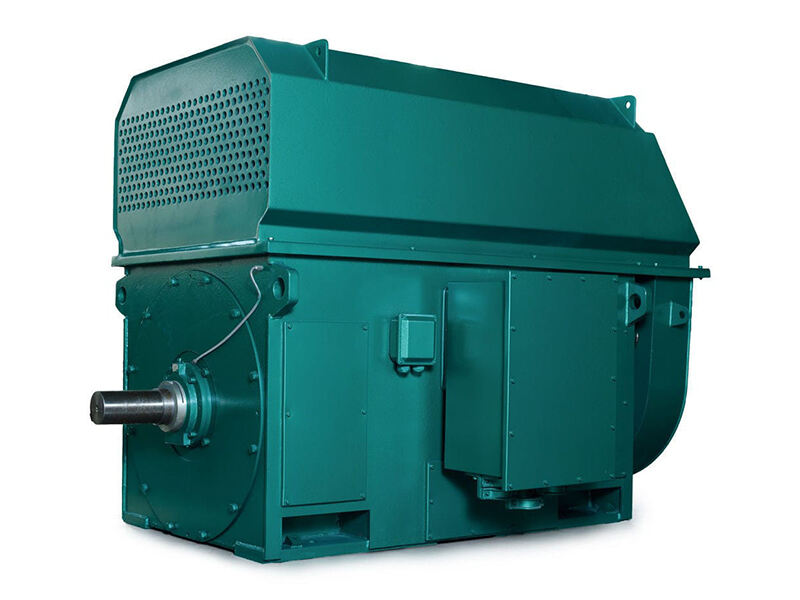

High voltage AC motors are critical components in water treatment plants, powering essential equipment such as pumps, aerators, mixers, and filtration systems that drive the purification, distribution, and wastewater treatment processes. Operating at voltages between 3kV and 11kV, these motors deliver the high power and consistent performance required to handle large volumes of water—often millions of gallons daily—while withstanding the demanding conditions of treatment facilities, including exposure to moisture, chemicals, and abrasive particles. In water treatment, pumps are used for tasks like raw water intake, sludge transfer, and treated water distribution, requiring motors that can operate continuously with minimal downtime. High voltage AC motors for these applications feature robust construction, including corrosion resistant enclosures (often made from stainless steel or epoxy coated cast iron) to resist damage from chlorinated water, acids, and alkalis used in treatment processes. Their insulation systems are designed to withstand high humidity, preventing electrical breakdown and ensuring long term reliability. Aerators, which introduce oxygen into wastewater to facilitate biological decomposition, rely on high voltage AC motors to drive impellers or diffusers at precise speeds. Here, the motors’ ability to maintain stable rotational speeds—often controlled via VFDs—ensures optimal oxygen transfer efficiency, which is critical for effective pollutant breakdown. VFD integration also allows for speed adjustment based on water quality metrics, such as biochemical oxygen demand (BOD), optimizing energy use and reducing operational costs. Mixers, used to blend chemicals for coagulation or flocculation, benefit from the motors’ high torque, ensuring uniform mixing even with viscous sludge. High voltage AC motors in water treatment plants also prioritize energy efficiency, as these facilities are among the largest energy consumers in municipal infrastructure. By operating at higher voltages, they minimize transmission losses, and when paired with VFDs, they avoid the energy waste associated with constant speed operation during low demand periods. Safety features, such as overload protection and water ingress sensors, prevent motor damage and ensure compliance with environmental regulations. Additionally, these motors are designed for easy maintenance, with accessible components that simplify inspections and repairs, reducing downtime in facilities where uninterrupted operation is vital to public health. Whether in drinking water treatment or wastewater recycling, high voltage AC motors enable water treatment plants to meet strict quality standards, ensuring safe, clean water for communities and industries.