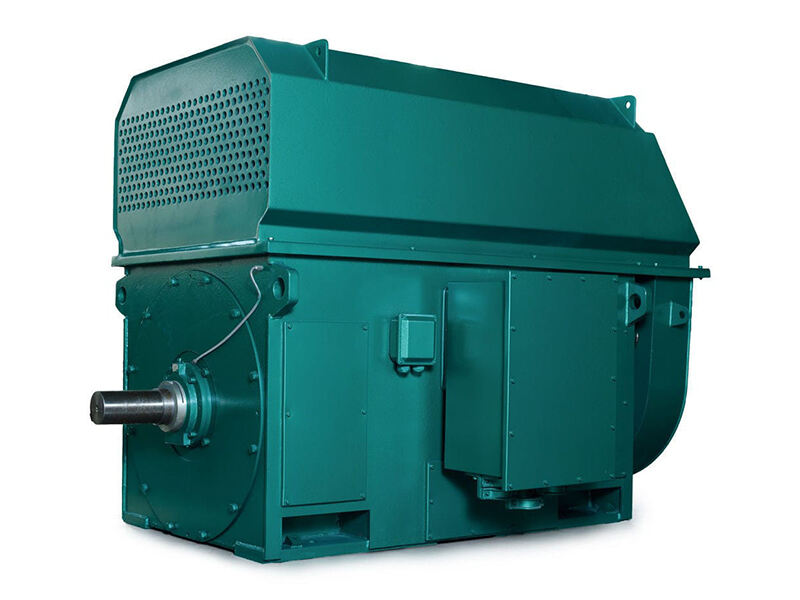

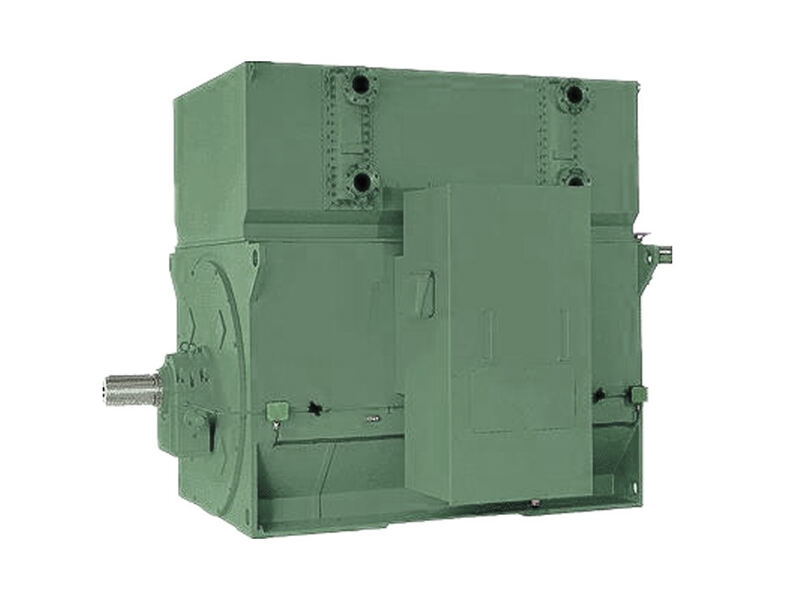

High voltage AC motors play a pivotal role in modern automotive manufacturing facilities, powering a wide range of critical equipment that drives production efficiency and precision. In automotive plants, these motors are used in robotic assembly lines, conveyor systems, paint booths, and material handling equipment, where they deliver the high torque and variable speed control necessary for complex manufacturing processes. Operating at voltages typically ranging from 3kV to 11kV, these motors offer superior power density, allowing them to drive large machinery while occupying less floor space. Their ability to operate at variable speeds, often controlled by advanced variable frequency drives (VFDs), enables precise control over manufacturing operations, ensuring consistent product quality and adaptability to different production requirements. High voltage AC motors in automotive manufacturing are designed to withstand the demanding conditions of factory environments, including high levels of vibration, temperature fluctuations, and exposure to dust and debris. They feature robust construction with reinforced frames, high quality bearings, and efficient cooling systems to maintain optimal operating temperatures during continuous operation. Additionally, these motors contribute to energy efficiency in manufacturing processes, reducing overall energy consumption and lowering operational costs. Their reliability is crucial to minimizing production downtime, ensuring that automotive assembly lines can meet tight production schedules and maintain high levels of productivity.