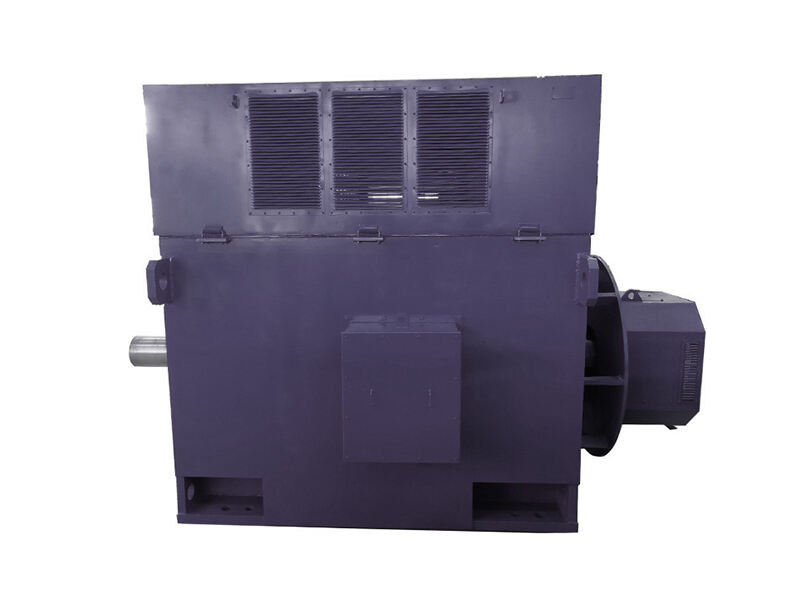

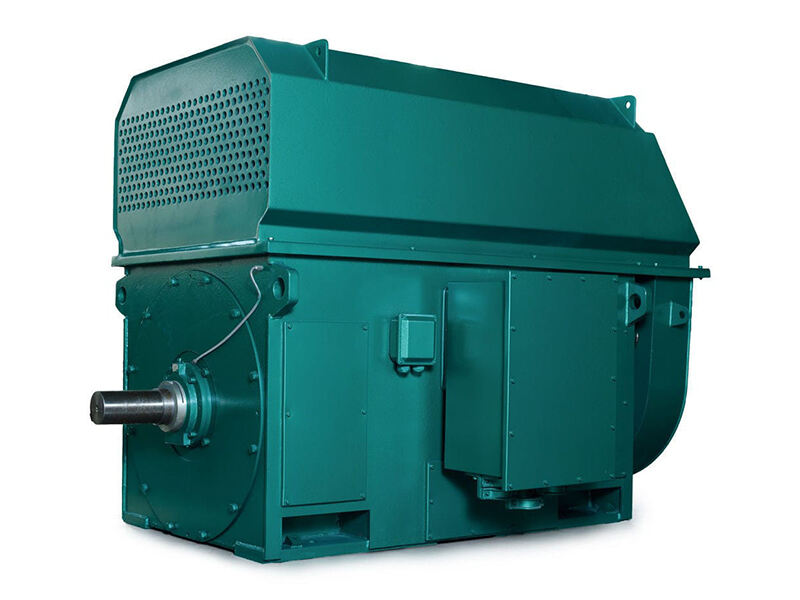

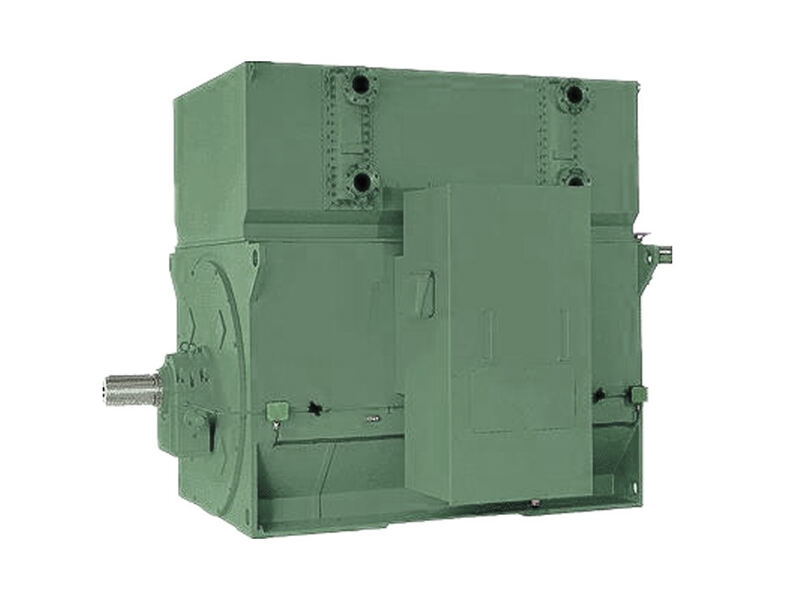

High voltage AC motors are essential for powering crushers in mining operations, where the efficient reduction of large rocks and ores into smaller particles is critical for mineral extraction and processing. These motors, typically operating at voltages between 3kV and 11kV, deliver the high torque and power required to drive jaw crushers, cone crushers, impact crushers, and gyratory crushers, which handle the demanding task of breaking down hard and abrasive materials. In mining environments, which are characterized by high levels of dust, vibration, humidity, and extreme temperatures, high voltage AC motors are designed with rugged features to ensure reliability and durability. This includes heavy duty enclosures to protect against dust and moisture ingress, reinforced frames to withstand severe vibration, and specialized cooling systems to prevent overheating during continuous operation. The ability of these motors to start under heavy loads is particularly important in crusher applications, where the initial load can be extremely high as the crusher engages with large rocks. High voltage AC motors are equipped with robust starting mechanisms, such as soft starters or VFDs, to minimize mechanical stress during startup and ensure smooth operation. Additionally, these motors contribute to energy efficiency in mining operations, as their higher voltage rating reduces energy losses and lowers electricity consumption. Regular maintenance, including lubrication of bearings and inspection of insulation systems, helps extend the service life of these motors, ensuring uninterrupted operation in the harsh and demanding conditions of mining sites.