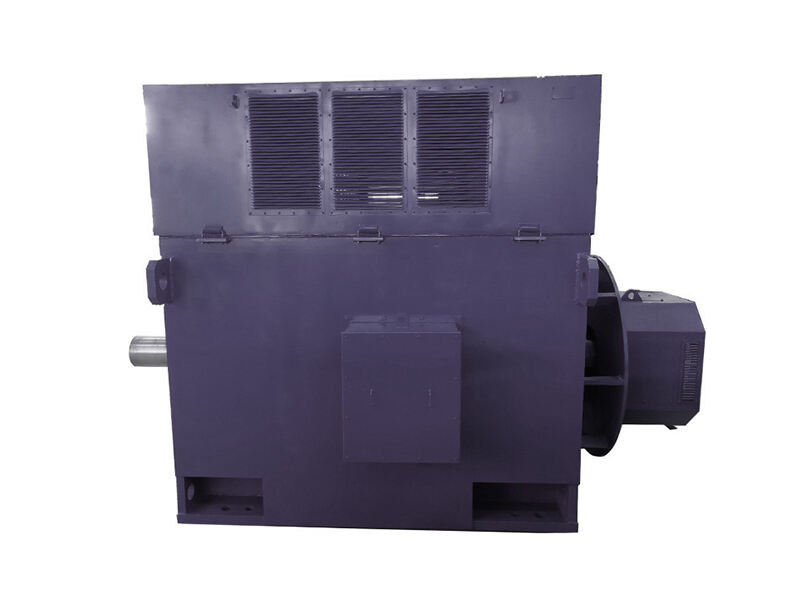

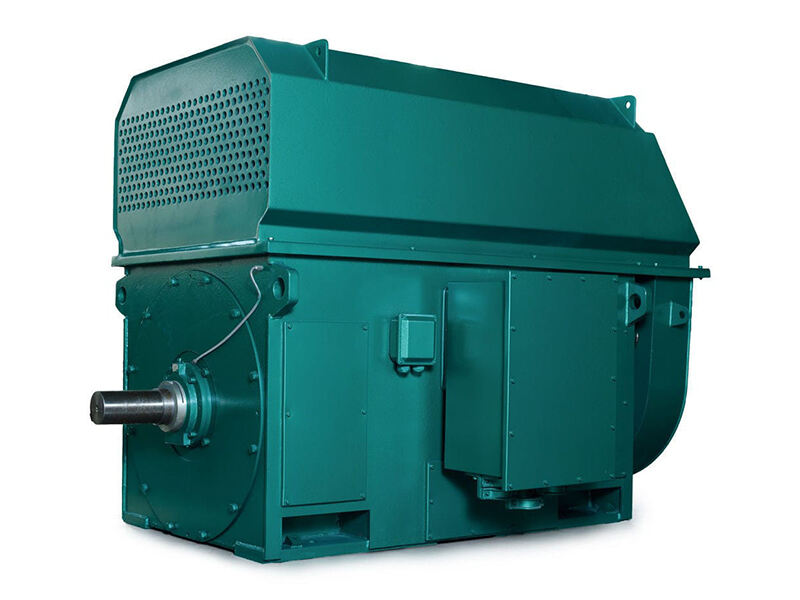

A high voltage AC motor paired with a variable frequency drive (VFD) forms an advanced, energy efficient system widely used in industrial applications where precise speed control, load management, and energy optimization are critical. The motor, operating at voltages from 3kV to 11kV, delivers high power and torque, while the VFD regulates its speed by adjusting the frequency and voltage of the electrical supply, converting fixed frequency AC power into variable frequency output. This integration addresses a key limitation of traditional fixed speed motors: their inability to adapt to varying load demands, which often results in energy waste and mechanical stress. In industrial settings such as manufacturing, mining, and water treatment, equipment like pumps, fans, and conveyors rarely operate at full load continuously. A high voltage AC motor with a VFD adjusts its rotational speed to match real time requirements—for example, slowing a pump when water demand drops or increasing a conveyor’s speed during peak production. This not only reduces energy consumption by up to 30 50% in variable load applications but also minimizes wear on mechanical components, extending their lifespan and reducing maintenance costs. The VFD also enables soft starting, gradually ramping up the motor’s speed instead of applying full voltage instantly. This eliminates the high inrush currents associated with direct on line starting, which can strain electrical grids and damage motor windings, while also reducing mechanical shock to connected equipment (e.g., gears, belts) during startup. Precision speed control is another key benefit, critical in processes like textile manufacturing (where thread tension depends on consistent roller speeds) or chemical mixing (where reaction rates rely on precise agitator rotation). Modern VFDs offer advanced features such as programmable logic controllers (PLCs), real time monitoring, and integration with industrial IoT (IIoT) systems, allowing operators to track motor performance metrics—temperature, current, vibration—and detect anomalies remotely. This predictive maintenance capability minimizes unplanned downtime. High voltage AC motors paired with VFDs are also designed to handle the harmonic distortions generated by VFDs, often incorporating insulated gate bipolar transistor (IGBT) technology and filters to ensure stable operation and compliance with electrical standards (e.g., IEEE 519 for harmonic control). Additionally, they support regenerative braking in applications like cranes or elevators, converting kinetic energy back into electricity and feeding it into the grid, further enhancing energy efficiency. In summary, this system combines the power of high voltage AC motors with the flexibility of VFDs, delivering a solution that optimizes performance, reduces costs, and enhances operational control across diverse industries.